NEWS AND EVENTS

-

1

Food safety in an era of pandemic

STERITECH is a developer of autoclaves and automated continuou...

01.02.2021

-

2

Confectionery production Monteur, Japan.

Monteur was founded in 1954 in Tokyo in the Adachi area, Senju...

21.01.2021

-

3

ROSER. Complete hygiene control.

ROSERGROUP is a world leader in the design and manufacture of ...

21.01.2021

-

4

Meat processing Tambov Bacon

Tambov Bacon is one of the largest meat processing plants in R...

21.01.2021

-

5

Opening of the Miratorg wholesale distribution center in Domodedovo

The NewLine Project Company thanks the Miratorg team, the ATP ...

24.09.2020

-

6

How Fake Food Became A $90 Million Industry In Japan

Fake food samples, or sampuru, can be seen in most restaurant ...

28.05.2020

-

7

How the Tabasco Factory Makes 700,000 Bottles of Hot Sauce Per Day

Head to the McIlhenny factory on Avery Island, Louisiana, wher...

28.05.2020

-

8

Coronavirus panic boosts pasta production in Italy

As the new coronavirus continues to spread across the world, p...

10.04.2020

-

9

Dupont gluten-free bread production

Global sales of gluten-free bread have risen sharply, with the...

27.03.2020

-

10

Restaurant industry in China, in the context of the coronavirus pandemic

The Haidilao restaurant chain that serves popular Chinese trad...

26.03.2020

-

11

Food centrifuge

A centrifuge used to separate product particles by density. Th...

11.03.2020

-

12

Ekiben. On-board meals in Japan

Ekiben (駅弁, railway boxed meals) are a specific type of...

09.03.2020

-

13

Byens Kokken Danemark social food

Mad & Måltider is a Danish social food company with a focu...

17.02.2020

-

14

ShowBOX technology and Tavil

Shelf-ready packaging (SRP), Show box - technology for packagi...

17.02.2020

-

15

High-speed manual production of burritos. Camino Real Kitchens, Vernon, USA

Ever wonder how the popular brand Tina's Burritos makes a ...

14.02.2020

-

16

Japanese vending machines history

The first vending machine in Japan was a tobacco vendor, which...

13.02.2020

-

17

Milano Ristorazione Social nutrition

Milano Catering SpA established by resolution of the City Coun...

23.01.2020

-

18

Textures

Transglutaminase

Japanese scientists discovered...

21.01.2020

-

19

FOSS Foodscan analytics

FOSS is the leading global provider of analytics for the food ...

20.01.2020

-

20

Arabic cuisine on an industrial scale

Efendi Fleischgroßhandel GmbH,

is one of the lead...

16.12.2019

all news

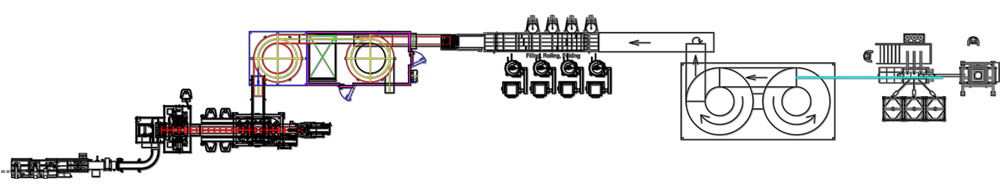

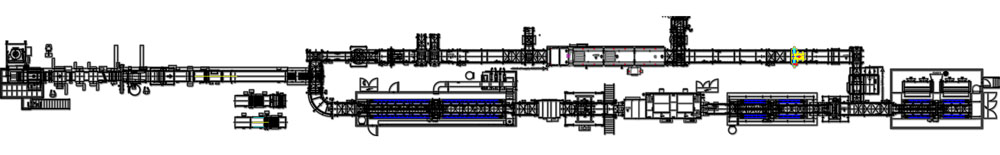

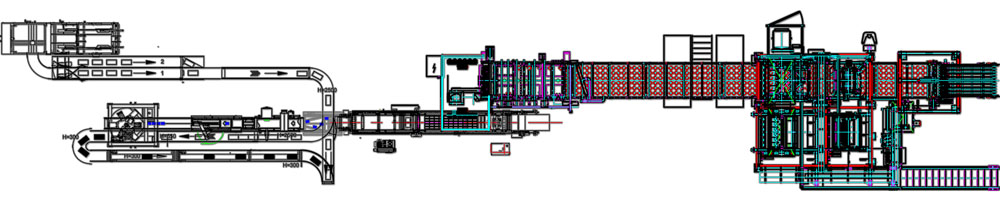

WE DESIGN EFFECTIVE FOOD-PROCESSING UNITS

We promote our innovative thinking through our strength of vision and team based diversified creative processes which in turn gives us the courage

and will to take on new opportunities by using new cutting edge approaches to the industry.

-

Vegetable preparation

-

Meat Processing

-

Meat Processing

WHO WE ARE

Newline-project is an integrated engineering design company with over 100 employees. The newline-project headquarters is located in the heart of Moscow.

Our team of engineers design, plan, and control independently tailor-made engineering and plant projects focusing on industrial scale production. We work from individual

processes to the general planning of extensive major industrial scale projects. Dealing daily on an international basis we speak English and Russian and provide translation

experts for all major world languages. With strong partners, we Combine competence and expertise to envisage, realise and put into process integral bespoke projects.

We do tailor made turnkey solutions from one source for ANY country in the world for more than 20 years and we continue to grow stronger by adding cutting edge

technologies and hands-on expert personel.

OUR SERVICES

- design

- engineering

- project management

- process optimization

OUR PRODUCT GROUPS

- Meat processing

- Ready meals production

- Bakery facilities

- Vegetable preparation solutions

3 steps to an individual successful solution

NEWLINE PROJECT - A TEAM OF PROFESSIONALS

- 20 YEARS OF EXPERIENCE

- HIGHLY QUALIFIED TECHNOLOGISTS

- HIGHLY QUALIFIED ENGINEERS

- PARTNERSHIP COOPERATION

- HIGHEST STANDARDS OF MORALITY AND ETHICS

SOLUTIONS FOR ANY CULTURE & COUNTRY

- INNOVATIVE SOLUTIONS COMBINED WITH LONG TERM EXPERIENCE

- TAILOR MADE TURNKEY SOLUTION FROM ONE SOURCE

- PROACTIVE PROJECT MANAGEMENT

- THE CREATION OF EFFICIENT PROCESSES

- THE USE OF TREND-SETTING TECHNOLOGIES

- REDUCED PROJECT RUN TIMES

- CUTTING OF INVESTMENT COSTS

WHAT WE DO

We develop technological solutions for industrial food production in different countries of the world for more than 20 years and we adapt local culinary traditions to modern technologies.

INTEGRAL PLANNING

1CONCEPT. PRELIMINARY PROJECT. FEASABILITY STAGE

Concept

- Working out objective targets.

- Determination of/working out planning basics.

- Draft of the production process.

- Principle basic design, alternatives.

- Overal cost estimate.

- Preliminary economic evaluation.

Preleminary project. Feasability stage

- Working out the production process.

- Working out the layout.

- Working out building services.

- Final overall cost calculation.

- Project schedule.

- Complete documentation.

Target: Preparation of a total concept, costs, economic efficiency, time schedule. Start of realization of architecture and building services.

2PROJECT. TECHNOLOGICAL SOLUTION. TENDER

This phase will produce the actual detailed information necessary for an Architect to design the actual building and to provide all of the services.

We will work with the Architect

to ensure that he has a complete understanding of the requirements of technological solution in terms of room specifications, temperatures, and wall and floor construction.

- Approval planning.

- Preparation of detailed tender documentation. (User Requirement Specification - URS)

- Evaluation.

- Coordination of the technical execution. (Utilits)

- Setting up and monitoring of the project schedule.

Target: Placing of orders, technical fine tuning between that of the of architect and building services.

3PROJECT MANAGEMENT

- Management of the project plan.

- Monitoring of installation.

- Management of commissioning.

- Management of acceptance.

- Management of correction of faults.

Target: A completely realized project.

4INSTALATION MANAGEMENT. STATIC INSTALATION. DRY TEST

Based on our experience in the major international projects, we know the challenges we will meet during the installation of the equipment and coordination of

all parties involved in the project. We offer the management of this important project phase by our competent expert team of engineers.

- Coordination and supervision of the FAT (Factory Acceptance Test)

- Support and technical supervision during installation.

- Interface management with all disciplines and suppliers involved in the project.

- Especially construction and domestic services, public test authorities.

- Management of the project schedule and documentation.

- Operation test.

5COMMISSIONING MANAGEMENT. DYNAMIC INSTALATION. TEST WITH PRODUCT

After the recorded end of installation of the equipment, the test phase will start and the equipment is put into operation.

A clean and transparent guidance as well as detailed coordination with all participants, if possible under centralized management,

will decrease costs and guarantee fast achievement of the performance data and efficient quality optimization.

- Coordination, supervision of the test operation with and without product.

- Functional test of the safety systems.

- Coordination, supervision of the commissioning.

- Coordination, supervision of the acceptance.

- Control of correction of faults.

6PROCESS OPTIMIZATION

We will analyze your current processes and identify your gaps.

- Detailed elaboration of your process as flow chart.

- Identification of your gaps.

- Elaboration of alternative solutions.

- Economic assessment.

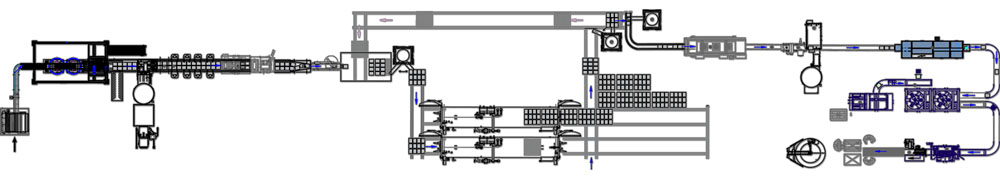

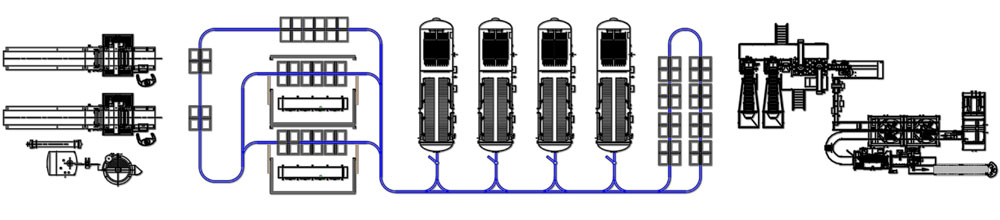

REFRIGERATING SYSTEMS

COLD STORAGES

We perform a full range of works for refrigerated storage and distribution centres with optimised

capital expenditure, energy consumption and reliability guarantees. First and foremost in the design

of cold storage facilities, our specialists consider possible ways of reducing the required cooling

capacity, suggesting measures to reduce heat gains, speed up logistics processes and introduce an

optimum level of automation. Only atier that is the technical soluti on chosen to minimise the cost

of running the refrigeration and related engineering systems as much as possible.

INDUSTRIAL FOOD UNITS

Modern food production is unthinkable without refrigerati on systems. In the process chain, a

product can go through freezing, rapid cooling, defrosting and temporary storage. In addition,

product processing takes place in refrigerated halls. Often there is a need to use ice water or ice

makers. The complete furnishing of food plants with refrigeration systems is already a traditional

part of NEW LINE’s activities. Regardless of the complexity of production, you can be sure that the

quality of your product will be maintained.

FREEZING, CHILLING

Freezing is one of the most delicate processes in the production chain. It requires a precise approach,

experimental forecasting and repeated experiments. These aspects aff ect the shelf life

of the product and its appearance atier defrosting and cooking. Depending on the technological

processes in production, NEW LINE implements diff erent methods of freezing: in slab or

spiral freezers, in cabinets or prefabricated blast chambers.

VENTILATION

Virtually any building cannot do without ventilation and air conditioning systems. NEW LINE specialists

develop projects based on current regulations, using state-of-the-art equipment and selecting equipment

that takes into account the loss of condensation capacity. This ensures optimum air velocity and

no lack of capacity. Particular attention is paid to the calculation of canopies. Energy-saving solutions

such as recirculation and air recuperation are applied.

TECHNOLOGICAL SOLUTIONS FOR INDUSTRIAL FOOD PRODUCTION

Automatic roasting solution

Bread production

Ready meals sterilization

Sandwich production

Sublimation solution

CONTACTS

NewLine-Project

Office

1, bldg.1, Volokolamskoe shosse, Moscow, Russia, 125080

Phone

+7 499 800 40 01

E-mail

Telegram

Данный веб-сайт https://newline-project.com использует аналитические файлы cookie для оптимизации своей работы и улучшения работы пользователей с ним,

а также статистические файлы cookie для отслеживания статистики посещений веб-сайта. Нажимая кнопку «Закрыть ×»,

Вы соглашаетесь на использование нами указанных файлов cookie в соответствии с нашей Политикой в отношении файлов cookie.

По своему желанию клиент в любой момент может предотвратить отслеживание своих действий, отключив Cookies в своем браузере.

Согласие на обработку персональных данных

Настоящим в соответствии с Федеральным законом № 152-ФЗ «О персональных данных» от 27.07.2006 года свободно, своей волей и в своем интересе выражаю свое безусловное согласие на обработку моих персональных данных ООО "Новая Линия", зарегистрированным в соответствии с законодательством РФ по адресу:

125080, г. Москва, Волоколамское шоссе, дом 1, стр. 1 пом/ком. IV/34E (далее по тексту - Оператор).

Персональные данные - любая информация, относящаяся к определенному или определяемому на основании такой информации физическому лицу.

Настоящее Согласие выдано мною на обработку следующих персональных данных:

Фамилия, Имя, Отчество пользователя; номера телефонов; IP-адрес; адрес электронной почты (E-mail).

Также на сайте https://newline-project.com происходит сбор и обработка обезличенных данных о посетителях (в т.ч. файлов «cookie») с помощью сервисов интернет-статистики Яндекс Метрика, это инструмент веб-аналитики позволяет помогает получать наглядные отчеты, записи действий посетителей, отслеживать источники трафика и оценивать эффективность онлайн - и офлайн-рекламы.

Согласие дано Оператору для совершения следующих действий с моими персональными данными с использованием средств автоматизации и/или без использования таких средств: сбор, систематизация, накопление, хранение, уточнение (обновление, изменение), использование, обезличивание, а также осуществление любых иных действий, предусмотренных действующим законодательством РФ как неавтоматизированными, так и автоматизированными способами.

Данное согласие дается Оператору для обработки моих персональных данных в следующих целях:

предоставление мне услуг / работ; направление в мой адрес уведомлений, касающихся предоставляемых услуг / работ; подготовка и направление ответов на запросы; направление в мой адрес информации, в том числе рекламной, о мероприятиях / товарах /услугах/ работах Оператора.

Обезличенные данные Пользователей, собираемые с помощью сервисов интернет-статистики, служат для сбора информации о действиях Пользователей на сайте, улучшения качества сайта и его содержания.

Оператор обеспечивает сохранность персональных данных и принимает все возможные меры, исключающие доступ к персональным данным неуполномоченных лиц. Персональные данные Пользователя никогда, ни при каких условиях не будут переданы третьим лицам, за исключением случаев, связанных с исполнением действующего законодательства или при получении прямого согласия пользователя на передачу его персональных данных третьему лицу.

Настоящее согласие действует до момента его отзыва путем направления соответствующего уведомления на электронный адрес helpme@skydentpro.ru. В случае отзыва мною согласия на обработку персональных данных Оператор вправе продолжить обработку персональных данных без моего согласия при наличии оснований, указанных в пунктах 2 – 11 части 1 статьи 6, части 2 статьи 10 и части 2 статьи 11 Федерального закона №152-ФЗ «О персональных данных» от 27.06.2006 г.